"Scream with happiness" - but virtually secured.

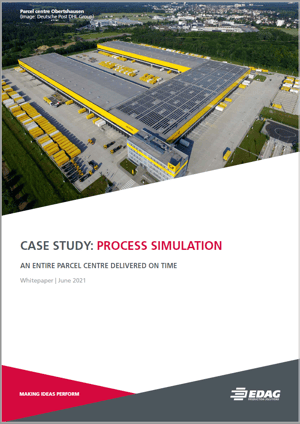

For the consumer, it's just a few clicks in the online shopping portal and a short time later the mailman is at the door. That is more or less all that today's shopping queens and kings perceive of the ordering process. For this process to work smoothly and for the desired bikini to be in the parcel at the end, the delivery processes must mesh flawlessly. The logistics company Deutsche Post DHL Group has put Germany's largest parcel center into operation in Obertshausen in southern Hesse. On a total area of five soccer fields or 40,000 square meters, 50,000 parcel shipments per hour can be sorted thanks to the integration of state-of-the-art technology. By comparison, previous parcel centers have a sorting capacity of between 30,000 and 40,000 items per hour.

For the consumer, it's just a few clicks in the online shopping portal and a short time later the mailman is at the door. That is more or less all that today's shopping queens and kings perceive of the ordering process. For this process to work smoothly and for the desired bikini to be in the parcel at the end, the delivery processes must mesh flawlessly. The logistics company Deutsche Post DHL Group has put Germany's largest parcel center into operation in Obertshausen in southern Hesse. On a total area of five soccer fields or 40,000 square meters, 50,000 parcel shipments per hour can be sorted thanks to the integration of state-of-the-art technology. By comparison, previous parcel centers have a sorting capacity of between 30,000 and 40,000 items per hour.

Putting the parcel center through its paces even before commissioning

EDAG Production Solutions supported DHL in gradually ramping up the new high-tech parcel center over a period of several months until it was officially commissioned. For this purpose, the two EDAG PS divisions Simulation and Production IT created a flexible emulation environment (FEU), which can be used for both simulation and virtual commissioning.

Every industry has its own challenges

EDAG PS has already successfully used the application of virtual commissioning in many different areas of industry. Obertshausen, currently Germany's largest parcel center with a targeted sorting capacity of 50,000 shipments per hour, was a new challenge for the engineering experts.

Download our case study now and benefit from our many years of industry expertise as a production solutions partner.